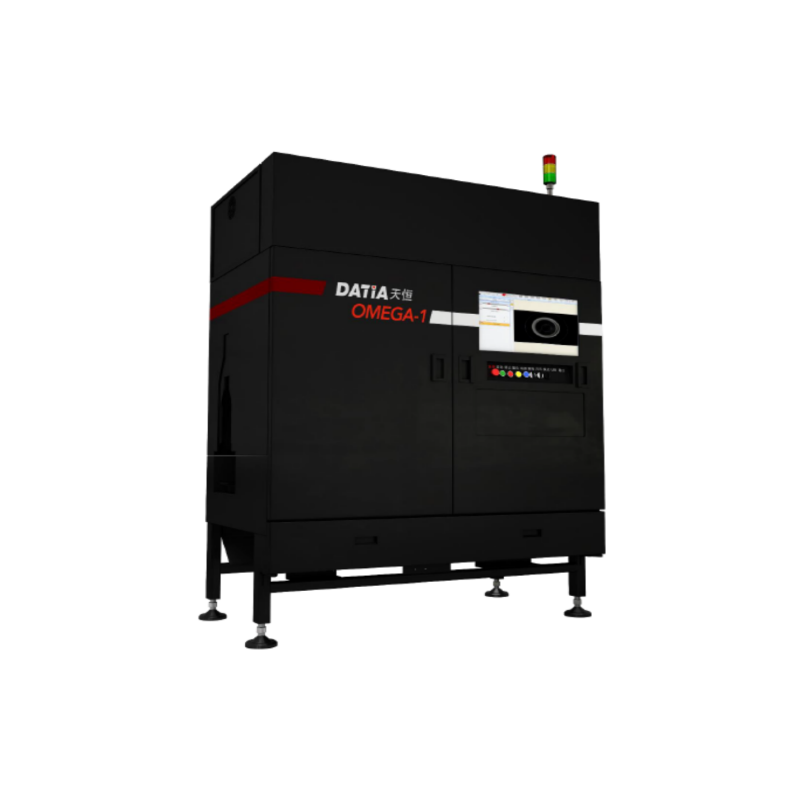

Features

The Omega inspection machine works for all kinds of glass containers, such as beer, wine and soda bottles.

• Straight on-line inspection system for all containers’products.

• Windows based operation system, openWebservice protocol.

• Customized LED light sources for finish and base.

• Compact size, efficient utilize of the space.

• Convenient adjustment for belt system.

• Based upon an international standard reliabletechnology, professional inspection algorithm.

• Defect recognitioncapability.

• Simple and efficient equipment structure,user friendly, adapted to all operators.

• Designed to meet glass container manufacturers’specific requirements.

Specifications

| Items | Values |

| Colourrangeforbottle | Flint, Green, Light Brown, others |

| Bottle shape | Round/Non-round |

| Height range | 35-420 mm standard features. Extended range upon request. |

| Diameter range | 20 – 175 mm standard features. Extended range upon request. |

| Inspection speed | Up to 450 BPM (Depending of the bottle type& Be inversely proportional to the bottle diameter) |

| Inspection items | • Finish defects (Overpress, line over finish, crizzle finish, finish abrasion) • Base defects (Base blister, stone, black spot, cracks, greasy dirt, bad mold seam, foreign objects) • Stress (Poor annealing, Stones, inclusion, deformed) • LNMP/LNMC Dot code reading and Alphanumeric code reading • WEM Wire edge measurement (Optional) • DSM Dip and Saddle measurement (Optional) |

| Power supply | 3 phase, 380V Dimension 1600mmx1100mmx (2200mm-2400mm (LxWxH) (Heightadjustable) |

021-52656086

021-52656086